Concerning: AMF quick-acting Toggle Clamps

AMF quick-acting toggle clamps incorporate the well known "toggle" principle. Their advantage being as follows:

- Large and quick opening, clearing the workpieces completely for unimpeded handling of work.

- Large power transmission. Minimum operating effort giving maximum clamping force.

- The clamps are self-arresting - they remain locked, resisting the force produced when machining components.

Applications:

A wide range of uses can be found for these AMF toggle clamps owing to their favorable power to movement ratio, and their easy action. These versatile clamps can be used in the metal working industry when drilling, welding, bending, grinding, testing and fitting, as well as in the wood and plastic industry in gluing, drilling, cutting and milling jigs.

Quality features

To rationalize effectively, a design should be selected which will function for many years. AMF toggle clamps are equipped with ample dimensioned rivets which are moving in case-hardened bushes (with exception of Sizes 0 and 1 for space reasons). All parts are galvanized prior to

assembly.

The tempered and galvanized damping screw (strength class 8.8) is quickly adjustable by the T-slot nut or the special nut. Certain toggle clamps are also available in "STAINLESS STEEL" versions.

Design and service Life

Due to the different applications the design is of importance. Besides our high quality standard types extra heavy duty toggle clamps (no. 6811 A and no. 6812A ) are available.

Forces with hand- and pneumatic toggle clamps.

The selection at the correct toggle clamp size depends on the required clamping forces (refer to specification tables). The forces are shown in kN and one should distinguish between:

- Holding force F1 or F2

- Clamping force F3 or F4 and

- Piston force F5 (6 bar air pressure)

The clamping force is the force applied when closing the clamp, measured between the arms and the component. As opposed to the pneumatic toggle clamps the clamping forces of manual clamps can not be correctly formulated as it as dependent on the operator.

The holding force is the force the closed arm transmits to the workpiece, without itself being deformed when machine forces apply. When maximum force is reached, the hinged point goes over the dead center, there by insuring, that the action is locked and cannot be released until such time as the handle is returned to its original position.

Mounting possibilities

The bases are offered in three versions:

- Toggle clamps with horizontal base.

- Toggle clamps with vertical base, preferably used on welded construction and on webs.

- Toggle clamps with angle base, for front mounting.

With all toggle clamps the clamping screws are included in the price. Large quantities can be supplied without clamping screw if required.

|

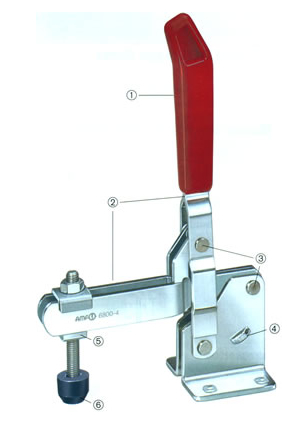

(1) The AMF toggle clamps are fitted with ergonomic handles. This is made of high quality oil-resistant plastic and guarantees an optimal handle force. The result of this is increased safety when using the toggle clamp.

(2) The vertical and push-pull type toggle clamps are actuated by equal acting movement of handle and clamping arm, the horizontal acting toggle clamps with opposite movement.

(3) Rivets of stainless steel set in case-hardened steel bushes ensuring durability and provide a consistent

performance.

(4) In most cases transposing of stop-pins is provided to allow two different opening angles.

(5) The clamping screw is positioned by means of a T-Nut, this is quickly adjustable and corresponds with

tensile strength class 8.8.

(6) The enclosed clamping screw is fitted with a removable oil-resistant rubber cap.

Specifications subject to change without prior notice.

|